Your partner for technology.

Full control with maximum power.

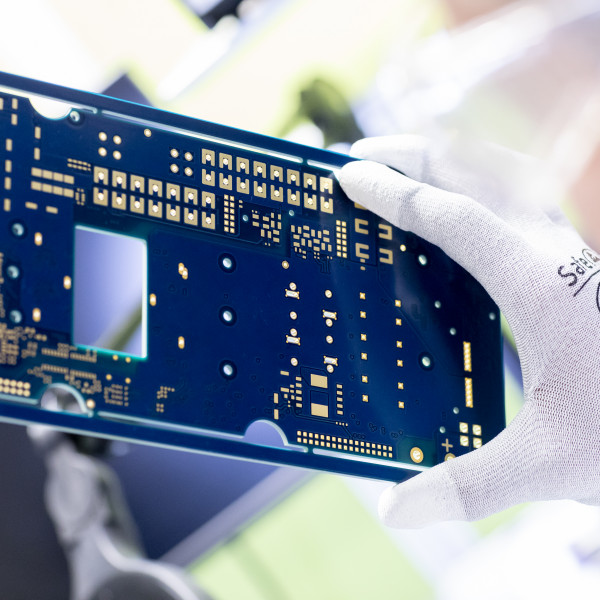

As a strategic technology partner, we develop and manufacture high-quality power electronics for our customers in Germany.

With strong expertise and maximum efficiency, we are already shaping the future of tomorrow.

Electronics - our passion.

Intelligent technology that inspires.

Our power electronics portfolio ranges from miniature and compact controllers to complex safety-related controllers for industrial trucks, construction machinery and agricultural machinery. This is complemented by the field of control electronics and functional safety to form an all-round package of electronic innovation.

Innovative, customer-oriented and flexible.

Your partner for professional electronics.

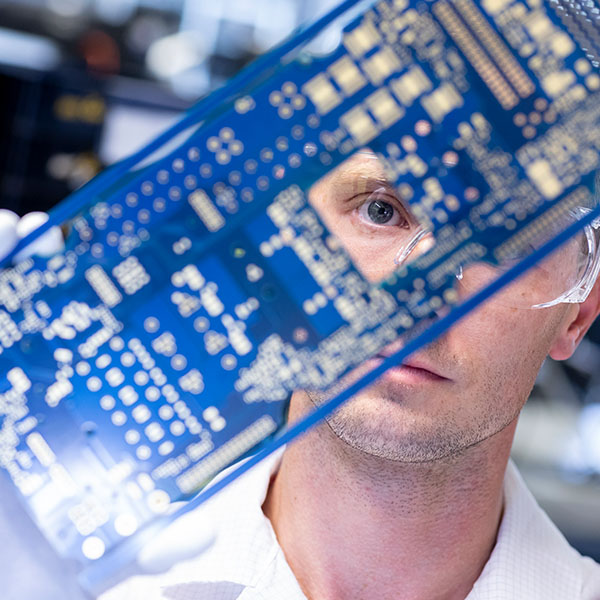

Tradition and innovation go hand in hand for us. The development of innovative solutions has always been part of our everyday work. Our interdisciplinary teams of experts will accompany your company into a better future.

Our focus is on you, the customer: We develop customized solutions in the broad range of professional electronics solutions.

Fast.

Efficient processes and short paths get your projects moving quickly.

Long-term.

We see ourselves as your long-term partner. Our products are designed to last – just like our partnership.

Customer-oriented.

We are fully involved in partnership-based development – and keep you as a customer always in focus.

Flexible.

We respond flexibly to your requirements in order to find the right solution for you.

Made in Germany.

Our flexible and efficient processes make us the ideal partner for sophisticated electronics solutions. We develop and produce at the same location and are able to implement even complex requirements optimally thanks to short distances and processes.

Our range of solutions

-

Power Electronics

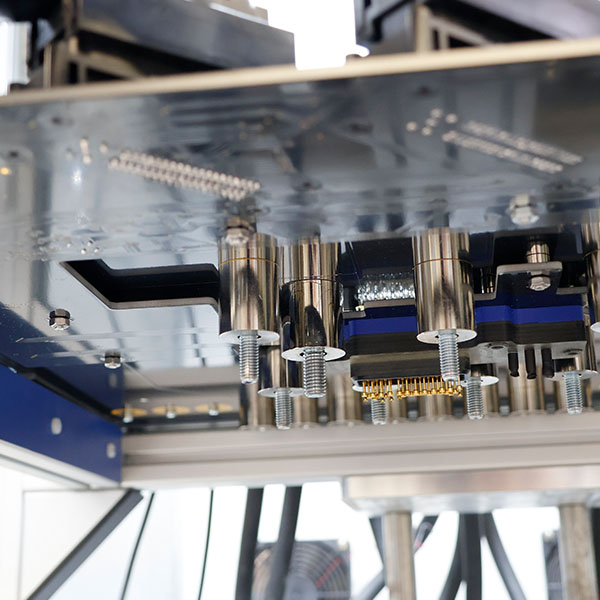

Power electronics are a key component for the efficient use of electric drives. Reliably converting and regulating voltages and currents – we make this possible thanks to our many years of know-how in development and production as well as series support for our customers.

-

Vehicle controls

With our electronic control systems the entire machine operation can be managed by a single component. They ensure optimum interaction between all electrical components in your vehicle or your work machine. All our products are of high quality, durable and suitable for even the most adverse environmental conditions.

-

Add-on-controls

Every requirement is individual: With additional modules, the most diverse tasks can be solved. For example, our guidance and navigation control systems enable the high-precision steering and coordination of autonomous vehicles. With add-on modules, we expand the customization options for your project.